can be combined with Type A milling head with the same diameter and bore.

Stark

STARK SpA, established in 1962 is a major manufacturer of wood working tools and world leader in the metal cutting field.

The headquarters and production facilities are located in Trivignano Udinese, Udine, Italy.

The Group boasts a network of strategically located distributors also thanks to its subsidiaries located all over the world: STARK GmbH & Co. in Germany and STARK TOOLS (Suzhou) Co., LTD. in China.

The strong points of the STARK Group are many:

- the organisation has been on the market for other 60 years, thereby a consolidated Customer Care service can be offered;

- the ISO 9001 certification guarantees the Customer a production process where quality and efficient after-sales assistance come first;

- the R&D divisions keep STARK at the forefront in the development of new products and in the supply of qualified technical assistance;

- the PVD department, which has become fundamental in the development of new treatment processes, thereby optimising product performance;

- the widespread network of Distributors and Sales Representative, which guarantees to our Customers to solve their needs with extreme competence and promptness.

can be combined with Type A milling head with the same diameter and bore.

can be combined with Type A milling head with the same diameter and bore.

can be combined with Type A milling head with the same diameter and bore.

Grooving cutterheads

grooving cutter bore 31,75mm (1-1/4 inch) TYPE B - 180 x 7.65 Z2

can be combined with Type A milling head with the same diameter and bore.

Profile-counterprofile cutterhead

Profile counterprofile cutterhead 120x40 Bore 30mm

Suitable for stock 22-25 mm

HW brazed cutter with spurs for making precision grooves with various thickness.The tool is complete with spacing rings.

MEC

MEC

knives are included

knives are included

knives are included

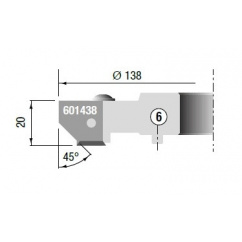

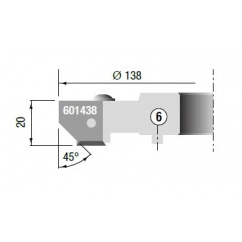

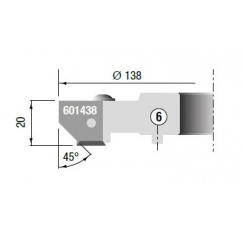

Cutterhead in light alloy with two knives for 45° joints for wood thickness 14 to 26mm.The joint is obtained by two subsequent working phases: the first with the piece being worked in horizontal position and the second with the piece of wood in vertical position.

2 HM knives included

Cutterhead in light alloy with two knives for 45° joints for wood thickness 14 to 26mm.The joint is obtained by two subsequent working phases: the first with the piece being worked in horizontal position and the second with the piece of wood in vertical position.

2 HM knives included

Cutterhead in light alloy with two knives for 45° joints for wood thickness 14 to 26mm.The joint is obtained by two subsequent working phases: the first with the piece being worked in horizontal position and the second with the piece of wood in vertical position.

2 HM knives included

Cutterhead in light alloy with two knives for 45° joints for wood thickness 14 to 26mm.

The joint is obtained by two subsequent working phases: the first with the piece being worked in horizontal position and the second with the piece of wood in vertical position.

2 HM knives included

MEC

MEC